SERVICES

Uncertified pre test for ITT examination

Air Permeability Test, water and wind resistance on a hardware (rif.EN14351-1 + A1, AAMA-101)

ITT Certification for windows and doors

Air Permeability Test, water and wind resistance on a hardware (rif.EN14351-1 + A1, AAMA-101)

CYCLIC tests on the accessories

Cyclic tests on windows and doors accessories in accordance with 13126-1/19 standards

CYCLIC tests on single-axle hinges

Determination of product string for single-axle hinges, in accordance with EN1935 standard

Determination of opening and closing resistance on windows and doors

Cyclic test in accordance with EN1191

Additional stress tests on accessories

Stress tests and distortion tests in accordance with 13126-1/19

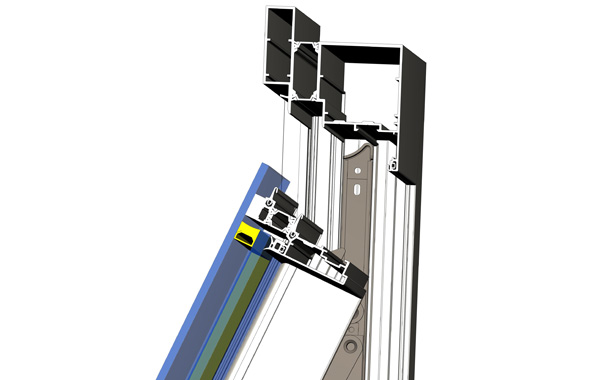

Thermal Certification for Nodes and Hardwares - rif. EN10077-1/2

- Validation of the calculation for thermal transmittance of nodes and hardwares (Uf)

- Calculation of thermal transmittance of complete doors and windows (Uw)

- Release of the test report (regardless of the number of nodes)

Report of extensibility of the results of ITT - DIP tests

Declaration of functional equivalence on the interchangeability of the accessories

Determination of corrosion resistance

Neutral salt mist chamber tests in accordance with EN1670

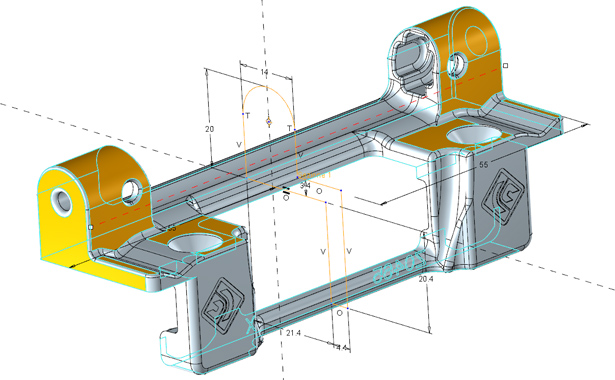

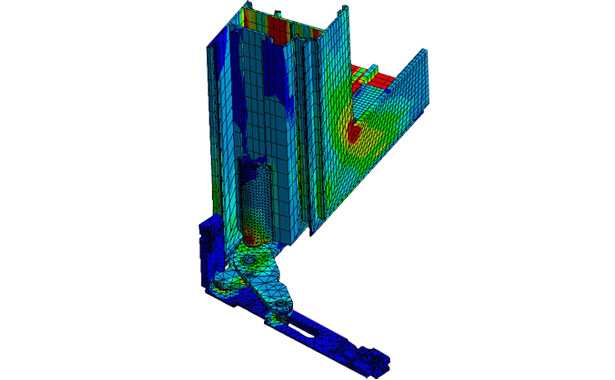

FEM verifications on mechanically stressed components

Calculation of the stress level through the analysis of finished parts

Tractive and compressive tests

Determination of the stress-strain curve

Dimensional measurements and characterisation of materials

Extruded profiles scanning, with automatic measurement of the percentage and control of tolerances. Microhardness tests on aluminium alloys.

Need more information about our services?